Pneumatic Pipebursting

Engineered for the Sewer Industry

Pneumatic pipe bursting systems were the first to be used extensively for the trenchless replacement of utility pipes. Historically, pneumatic systems have accounted for as much as 80% of the pipe bursting market annually. Whatever the requirements of your pipe replacement job, American Infrastructure Technologies Corporation can help you be successful. American Infrastructure Technologies Corporation pneumatic pipe bursting systems are configured to suit the specific conditions of your job site.

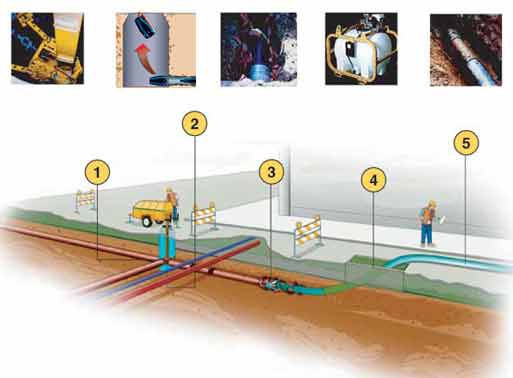

Typical Pneumatic Pipe Bursting Job Site

- HydroGuide winches are ruggedly built to meet the demands of pipe bursting. The winches are designed to facilitate extraction of burst heads through manholes to reduce the need for expensive receiving pits.

- Excavation costs can be reduced by utilizing mahole retrieval of the burst head. (Manhole exiting is a patented process of Earth Tool Company LLC, US PATENT: US 6,299,382 B1)

- A bursting head fitted to the American Infrastructure Technologies Corporation tool bursts damaged pipeline and pushes the fragments into the surrounding soil. As the tool bursts the pipe, new product of the same or larger size is pulled in.

- On larger or longer bursts, lubrication can increase production and the bursting distance capability by reducing pipe friction. The HB130 mixing system is designed for bursting applications and pipe lubrication.

- New product is attached to the pneumatic pipe bursting tool and is pulled into place as the tool follows and bursts the exising line.